Josh Levinson has been a Physical Therapist with Briotix Health for more than 6.5 years. Over that time, he has seen a wide range of client discomforts, each requiring their own care and treatment plan. However, recently Josh had to get creative to find a solution for a high-risk task that was causing discomfort for employees.

A Very Long Day Illustrates an Ergonomic Problem

One day, a client laboratory was understaffed resulting in one employee performing the work of three employees for more than 10 hours. Her job task over those 10 hours was to manually uncap small glass vials under a biohazard hood to test for contaminates. Unfortunately, the vial caps had been previously overtightened, and she could not easily uncap them. After her shift, she developed severe neck, shoulder, wrist, and finger pain which resulted in medical intervention. Josh was contacted by the company’s Health Services to provide ergonomic support and subsequent physical therapy.

As part of the ergonomic support, Josh completed an ergonomic analysis on the job tasks associated with the employee’s role. Upon evaluation, it was determined the uncapping of the vials was a high-risk task for all employees.

Developing a Prevention Solution with Additive Manufacturing

As a first step in preventing future injuries, Josh proposed administrative controls including more rest, stretch breaks, and ensuring proper staffing. And while these controls were put into place, the ergonomic task was still deemed high risk. Josh then began exploring engineering controls. After some trial and error, an electric screwdriver with a socket was initially successful in increasing sustainability and reducing risk but ended up contaminating the samples, so it could not be used. Then, Josh had a unique idea.

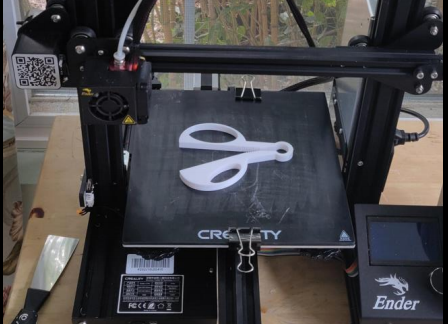

Having just recently purchased a 3D printer for home use, Josh began exploring the idea of printing his own engineering control. He had seen previously published designs for printed bottle openers available online and realized he could make some modifications to work for the vial cap.

Using a simple computer-aided design program on his home computer, Josh was able to quickly develop several on-demand prototypes and print them using a special heated filament. Each prototype took approximately 2.5 hours to print, and the material cost was approximately $2 per tool. Once all the prototypes were printed, Josh let his children play with the tools to test for durability and functionality. As a final step in the development phase, Josh tested the tools with onsite employees and made more revisions based on their feedback.

The final result - a small hand-held tool similar to plyers that has a round head with small teeth lining inside the head. Since the tool did not need special polymers and only used plastic, it could easily be reprinted using onsite 3D printing technology.

Fig. 1: Original High-Risk Task

Fig. 2: 3D-Printed Solution at Josh's House

Fig. 3: Modified task using printed tool.

A Successful Implementation Using 3D printing solutions

The work site was extremely excited about implementing Josh’s new tool. With the printed engineering control, the ergonomic task was no longer deemed high risk and the employee’s discomfort was completely resolved. With the successful outcomes associated with the tool use, company management mandated the tool be used in this lab by everyone. An easy manufacturing process only aided in this decision.

With today’s technology and knowledge of ergonomic issues, any provider can take the steps to find a creative solution for their client. Josh did not limit himself to pre-existing solutions to find exactly what the client needed. Josh's willingness to go above and beyond to find an innovative solution created the best possible outcome for his client's workforce.